Our team conceives original and sometimes unusual solutions and then implements those ideas into successfully-developed high-quality products that impress consumers.

We are committed to solving product development challenges by making the products durable and more cost-effective to our customers.

Our production engineering and design expertise provides our clients with the benefits of both speed and product quality.

Polyester Fabric Sdn Bhd Is A Largest FIBC Bulk Bags Manufacturer and Supplier In Malaysia. We Provide Fibcs, Also Known As Jumbo Bags, PP Woven Bags, Cargo Sling, PP Mono Webbing Belt, PP Laminated Tape Slitting Rolls, PP Laminated Fabric, PP Multifilament Yarn and Filler Masterbatch (Calcium Carbonate) . We as one of the leading manufacturer of jumbo bags, We manufacturing and selling our products throughout Asia and almost 30% is in the nature of exports. Our product is very well accepted in the Asia market for its QUALITY, FINISH, WEAVES, STRENGTH and COLOURS.

So that our company well known as a “SUPER” Company where “SUPER” stands for:

S PECIALIZED IN PP PRODUCTS

U NBEATABLE PRICE FOR SUPERIOR QUALITY

P ERFECT MANUFACTURING “NEAR ZERO DEFECTS”

E XCELLENT QUALITY

R EAL “ON TIME DELIVERY” OF GOODS

Our habit of delivering high quality products to our customer which meets their exact requirements, have given our customer complete satisfaction on our services. We carry all our work process in customer centric approach so that our customers are always at ease while doing business with us.

We offer unique & customized packaging solutions in terms of weight, dimensions and methods to offer the right fit for our customer. We offer our products in pallet, shrink wrap packaging or packed in special plastic bags before putting into cartons.

Polyester Fabric Sdn Bhd believes in and practices a “quality at the source” philosophy to ensure all products and services meet or exceed our customers requirements and satisfaction. As individuals, we always follow strict procedures and policies and assure we do it every time. As a team, we always strive to wisely improve our products and processes.

First ControlChecking every incoming raw materials according to specifications. Validate every production process to eliminate work in process error.

Process ControlOn line monitoring in every production process to avoid error at the end. Keeping record of process data to improve process performance.

Final ControlChecking finished product of each production department to eliminate error for the next. Ensuring a perfect end product to customer hand.

It is the original polypropylene design, Four-Panel Bulk Bags (FIBCs) have seams along four separate pieces of fabric that are sewn together to construct the body of the bag as well as having the top and bottom panels sewn in. Four-Panel bags tend to hold their shape better than other types of bags and are better suited for stacking.

Two Type Of Thickness; 0.13Mm~0.18Mm And 0.3Mm~0.35Mm and also Have Three Variation Of Paper Core Size (Id) Which Are 54Mm, 76Mm, And 152Mm.

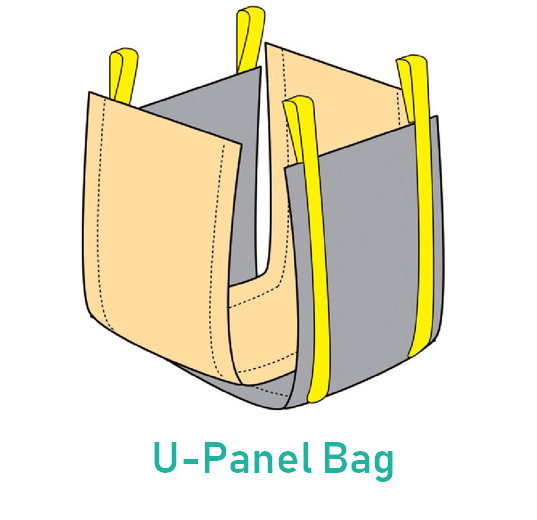

Two piece, U-Panel construction that has two seams sewn along the two opposite sides to create two panels, creating a “U” Panel shape. Accepted as the industry standard around the world, the U-Panel FIBC is the most popular FIBC shape. This construction gives the bag a large lifting capacity.

Two Type Of Thickness; 0.13Mm~0.18Mm And 0.3Mm~0.35Mm and also Have Three Variation Of Paper Core Size (Id) Which Are 54Mm, 76Mm, And 152Mm.

Baffle offers maximum stability. Four rigid cross corner loops sewn allow the forklift operator to pick up bags without the requirement of additional staff. The Baffle Bag is ideal for light-density products.Another advantage is the increased stack-ability and with all sewn edges turned to the outside, it reduces potential of contamination.

A Circular or Tubular bag. This created for a more aesthetically pleasing bag, and with only a top and bottom panel sewn into the bag, they are ideal for fine and hydroscopic materials. This design is ideal as a liner-less option for fine materials and is recognized for its ease of lifting and manipulating with a forklift.

The Conical Bag is designed specifically to assist in the complete discharge of contents, which are slightly sticky, like brown sugar and premix flour products. The conical shape at the bottom of the bag ensures that the bulk bag can be discharged quickly and easily.

Application:Compost SWL:1ton Size:1100*1100 Top:Skirt Bottom:Skirt Loop:Bottom full-sling loops

Application:All kinds of products SWL:1ton Size:1100*1100 Top:Skirt Bottom:Charge Spout Loop:Bottom full-sling loops

Application:Crops, Building materials SWL:1ton Size:1100*1100 Top:Skirt Bottom:Flat Loop:十Type loops

Application:Resin SWL:1ton Size:900*900*1200 Top:Skirt Bottom:Flat Loop:Bottom full-sling loops

Application:Feed SWL:1ton Size:900*900*1200 Top:Fill Spout Bottom:Charge Spout Loop:Bottom full-sling loops

Application:Ore SWL:1ton Size:900*900*1200 Top:Skirt Bottom:Charge Spout Loop:Bottom full-sling loops

72” NON-LAMINATED 72” LAMINATED 70” LAIMNATED 80” NON-LAMINATED

50” LAMINATED (LIGHT DUTY) 50” LAMINATED (HEAVY DUTY) 39” LAMINATED (HEAVY DUTY)

20MM WEBBING BELT 50MM WEBBING BELT 70MM WEBBING BELT 100MM WEBBING BELT